Description

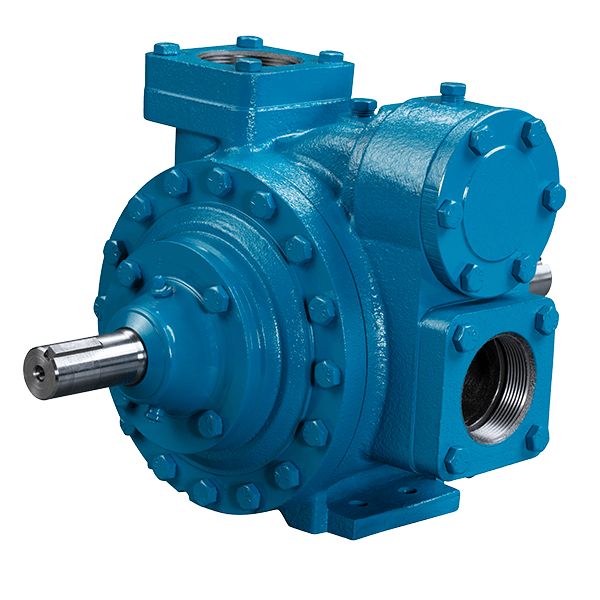

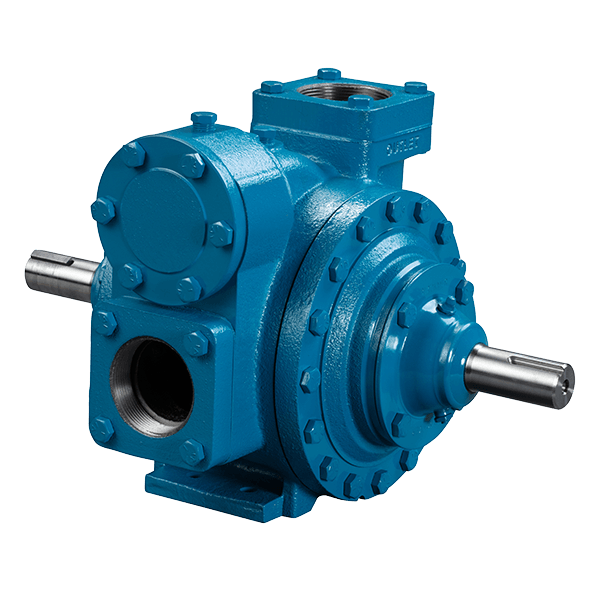

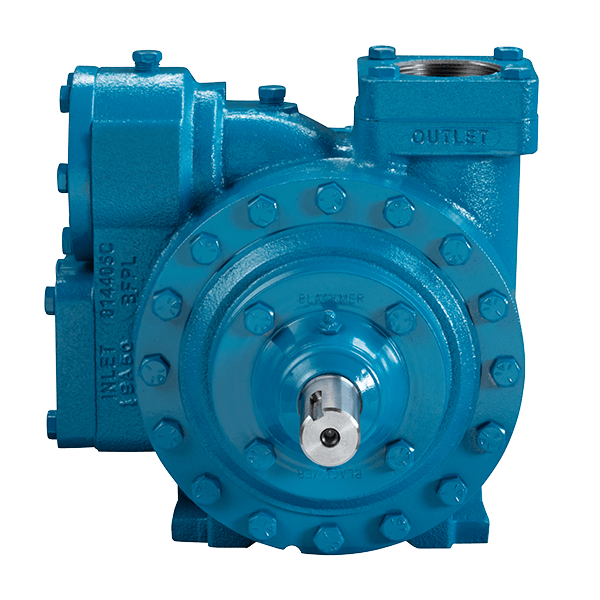

LGLD2-4 Sliding Vane Pumps

As part of the Cavitation Line of sliding vane pumps, these LGLD propane pumps are ideal for propane, LPG, butane and anhydrous ammonia applications including bulk plant service, multiple cylinder filling applications, vaporizers, bobtails and transports. All LGLD propane pump models have an internal relief valve, and a replaceable casing liner and end discs for easy rebuilding of the pumping chamber if ever necessary. In addition, these pumps feature cavitation suppression liners to reduce noise, vibration and wear.

Blackmer® LGLD2 propane pumps are often mounted to the chassis of a bobtail, or to a steel pad that is welded to the tank. The 3- and 4-in rotary vane pump models can be mounted to a transport in a number of different ways, generally near or between the tank landing gear brackets.

Blackmer fully Integrated Unit Assemblies are the pre-engineered and pre-designed drop-in pumping solution. These unit assemblies, include motor, gearbox, baseplate, coupling safety covers, and a LGL Sliding Vane Pump (2, 3 & 4-inch size). No alignment required with these pre-configured fully Integrated Unit Assemblies as they are ready for immediate drop-in installation.

Performance and Specifications

AVAILABLE MODELS

- LGLD2

- LGLD3

- LGLD4

NOMINAL FLOW RATE RANGE

- LGLD2: 30 – 105 gpm (114 – 397 L/min)

- LGLD3: 60 – 201 gpm (227 – 761 L/min)

- LGLD4: 150 – 370 gpm (568 – 1,400 L/min)

MIN/MAX SPEED (rpm)

- LGLD2: 350 – 980

- LGLD3: 350 – 980

- LGLD4: 350 – 800

VISCOSITY

- 0.2 – 10 cP

VANE MATERIALS

- Duravane

MAXIMUM WORKING PRESSURE (MAWP)

- 350 psi (24.1 bar)

CONNECTION ORIENTATION

- Side Inlet | Top Outlet

DIFFERENTIAL PRESSURE

- 150 psi (10.3 bar)

PRIMARY MATERIALS OF CONSTRUCTION

- Ductile Iron

TEMPERATURE

- -25°F to 240°F (-32°C to 115°C)

AVAILABLE CERTIFICATES

- Hydrostatic Test

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimensional (pump only or unit)

Reviews

There are no reviews yet.