Description

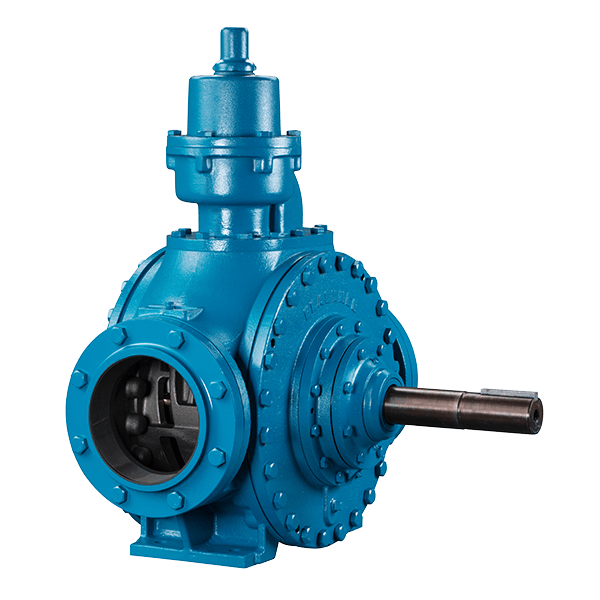

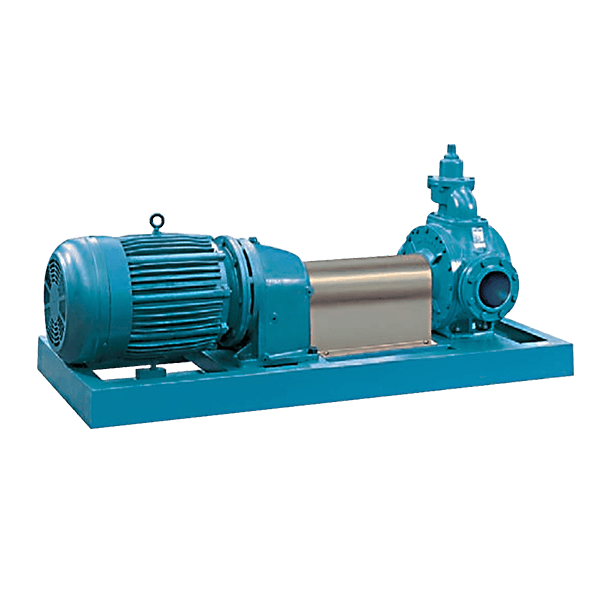

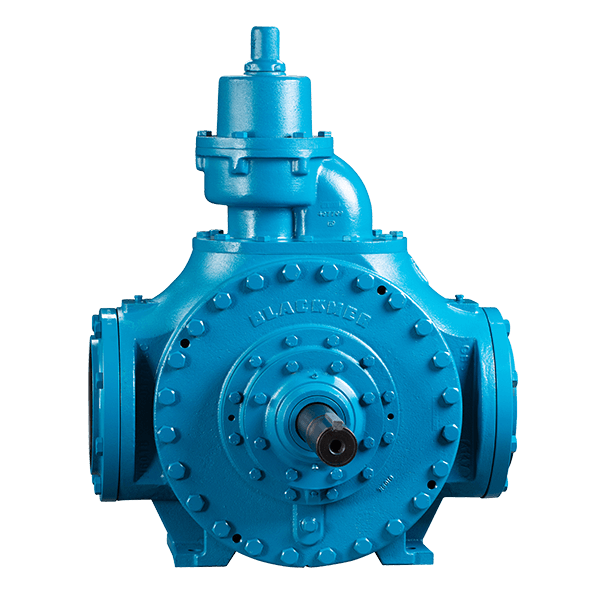

HXL Sliding Vane Pumps

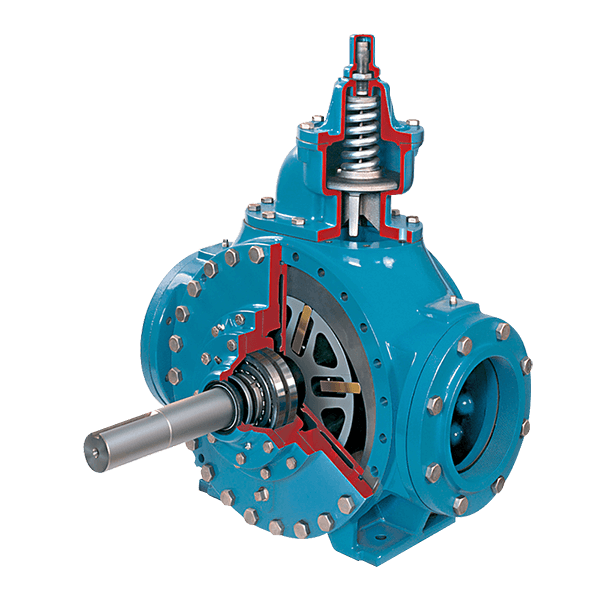

Utilizing the unique Blackmer® sliding vane design, these Heavy Duty Line positive displacement rotary pumps offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost.

The HXL pumps are constructed of ductile iron (ASTM 536) that will withstand sudden thermal shock and stress well beyond the capabilities of cast iron. All models are fitted with replaceable casing, liners and end discs that allow easy rebuilding of the pump, without removing the pump from the piping. Models are available in 6-, 8- and 10-in ANSI flanged port sizes with maximum rated capacities of 755, 1,200 and 2,080 gpm (171, 273, 472 m3/h) respectively. Standard elastomers include FKM O-rings. Optional bolt-on relief valves are designed to protect the pump from excessive pressure are available for all sizes.

Performance and Specifications

AVAILABLE MODELS

- HXL6

- HXL8

- HXL10

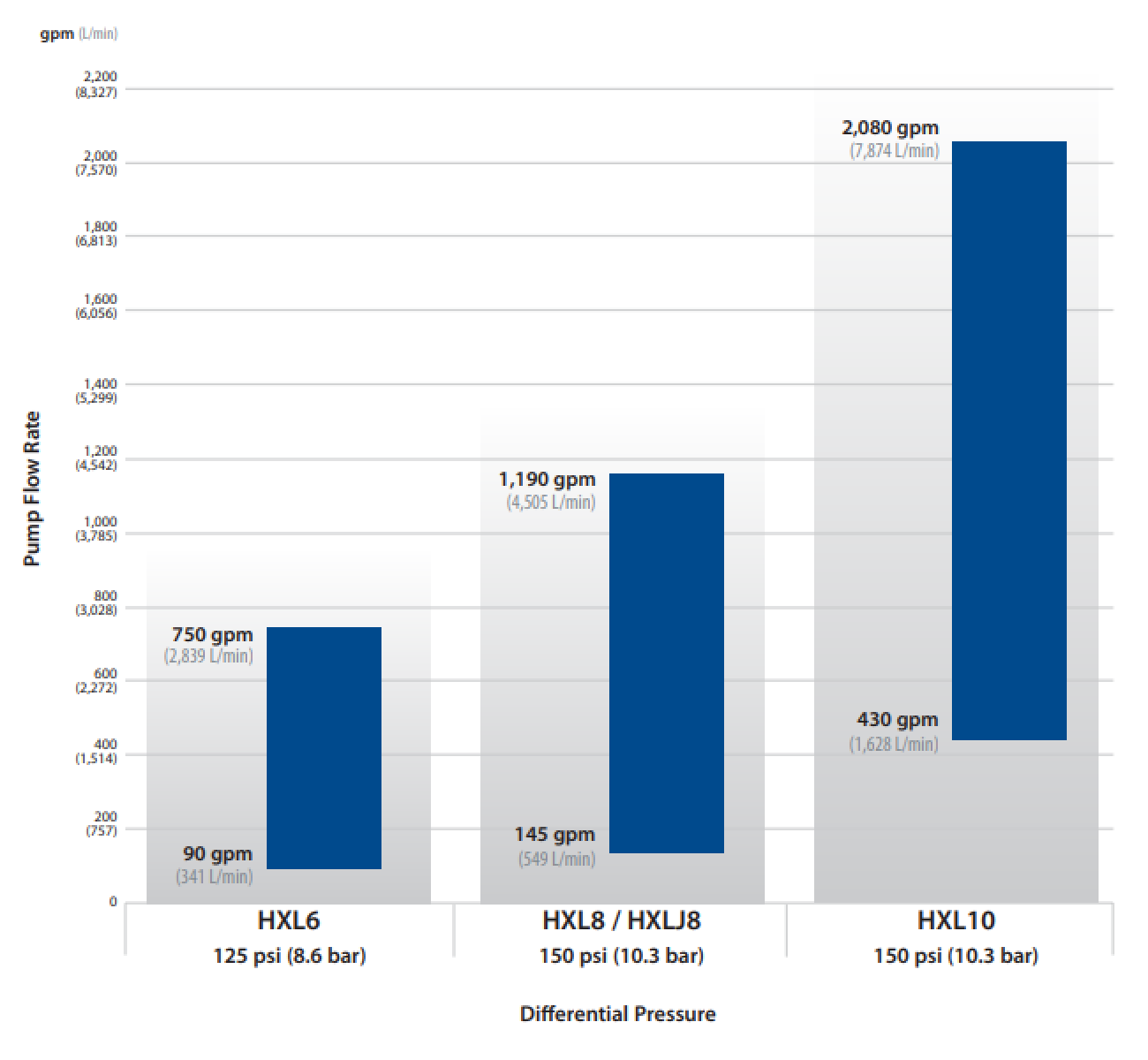

NOMINAL FLOW RATE RANGE

- 6″: 90 – 750 gpm (341 – 2,839 L/min)

- 8″: 145 – 1,190 gpm (549 – 4,505 L/min)

- 10″: 430 – 2,080 gpm (1,628 – 7,874 L/min)

VANE MATERIALS

- EC Laminate

- Bronze

- Iron

VISCOSITY

- 0.2 – 22,000 cSt

TEMPERATURE

- -25°F to 400°F (-32°C to 204°C)

CONNECTION ORIENTATION

- Side Inlet / Side Outlet

DIFFERENTIAL PRESSURE

- 6″: 125 psi (8.6 bar)

- 8″ & 10″: 150 psi (10.3 bar)

MIN/MAX SPEED (rpm)

- 6″ & 8″: 45 – 350

- 10″: 45 – 230

MAXIMUM WORKING PRESSURE (MAWP)

- 6″: 150 psi (10.3 bar)

- 8-10″: 250 psi (17.2 bar)

PRIMARY MATERIALS OF CONSTRUCTION

- Ductile Iron

CATALOG OPTIONS

- Connections: NPT, ANSI Flange

- Elastomers: FKM

- Seal: Blackmer’s single mechanical

- Bypass Valve: internal or external

AVAILABLE CERTIFICATES

- Hydrostatic Test

- Performance Test

- Material (actual or typical)

- Dimensional (pump only or unit)

Reviews

There are no reviews yet.