Description

NP Series Sliding Vane Pumps

Specifically designed to offer maximum versatility for handling a wide variety of clean non-corrosive liquids, NP Series Sliding Vane Pumps, which are part of the Iron Line, are a general purpose positive displacement pump ideal for applications where high temperature, high pressure, high viscosity and/or shaft sealing requirements dictate a sleeve bearing pump are used. The key to the NP Series’ versatility is the Blackmer® unique sliding vane rotor design that provides sustained, high level performance over a wide viscosity range. Slow operating speeds and non-pulsating flow minimizes shear and agitation of the fluid.

Performance and Specifications

AVAILABLE MODELS

- NP1.5

- NP2

- NP(H)2

- NP2.5

- NP(H)2.5

- NP3

- NP(H)3

- NP4

- NP(H)4

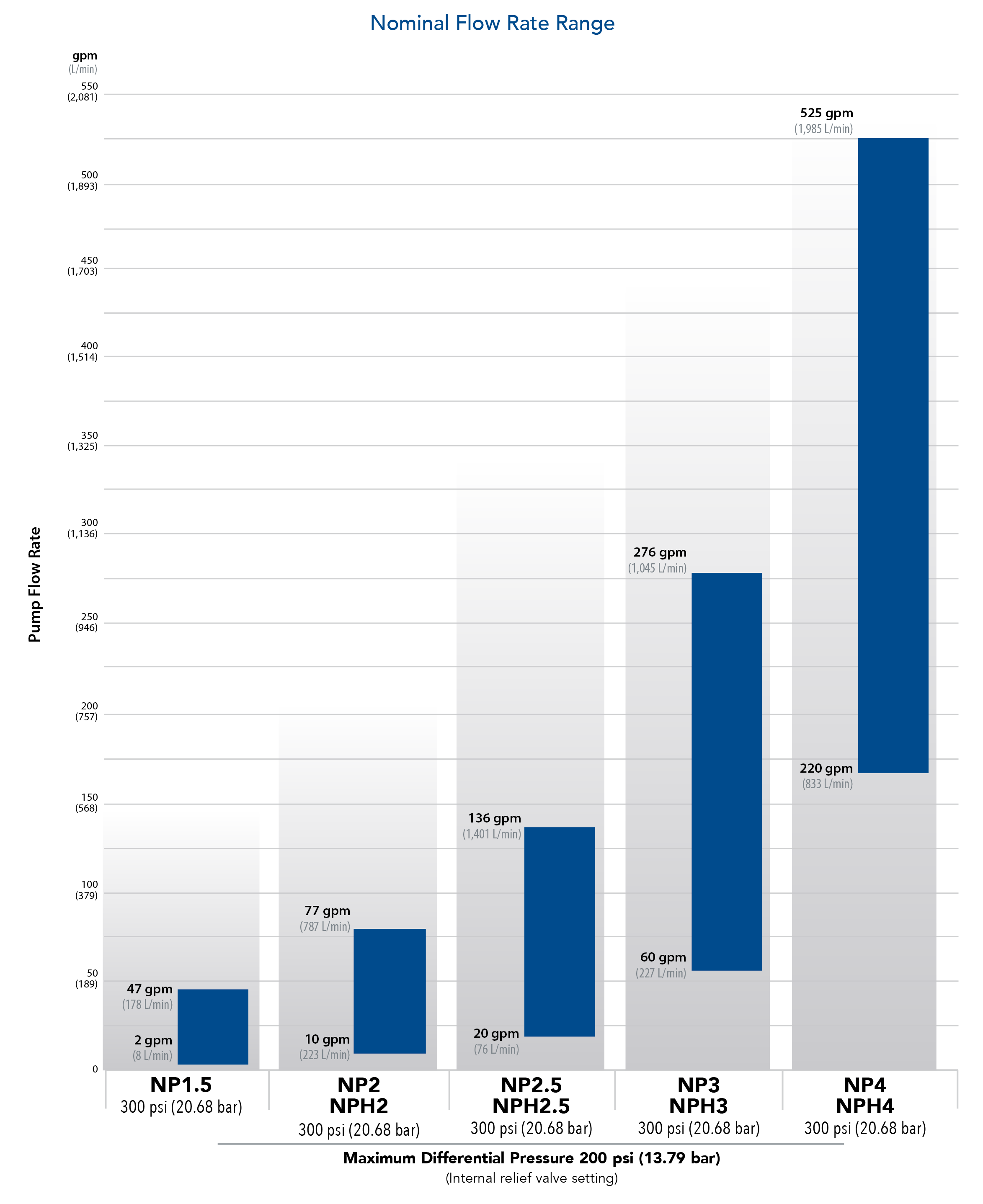

NOMINAL FLOW RATE RANGE

- 1.5″: 2 – 47 gpm (8 – 178 L/min)

- 2″: 10 – 77 gpm (38 – 291 L/min)

- 2.5″: 20 – 136 gpm (76 – 515 L/min)

- 3″: 60 – 276 gpm (227 – 1,045 L/min)

- 4″: 220 – 525 gpm (833 – 1,985 L/min)

DIFFERENTIAL PRESSURE

- 125 psi (8.6 bar) – Closed Rotor

- 200 psi (13.8 bar) – Open Rotor

MAXIMUM WORKING PRESSURE (MAWP)

- 225 psi (15.5 bar)

TEMPERATURE

- -25°F to 500°F (-32°C to 260°C)

VISCOSITY

- 0.2 – 4,250 cP – Closed Rotor

- 0.2 – 22,000 cP – Open Rotor

MIN/MAX SPEED (rpm)

- 1.5″ – 3 “: 70 – 640

- 4″: 70 – 520

PRIMARY MATERIALS OF CONSTRUCTION

- NP: Cast Iron

- NPH: Ductile Iron

CONNECTION ORIENTATION

- NP: Side Inlet | Top Outlet

- NPH: Side Inlet | Side Outlet

VANE MATERIALS

- Duravane

- EC Laminate

- Bronze

- Iron

CATALOG OPTIONS

- Heating Jackets: steam, oil, electric

- Connections: NPT, Weld, ANSI Flange

- Elastomers: BUNA, FKM, PTFE

- Seal: mechanical, packed, triple lip

AVAILABLE CERTIFICATES

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimensional (pump only or unit)

Reviews

There are no reviews yet.