Description

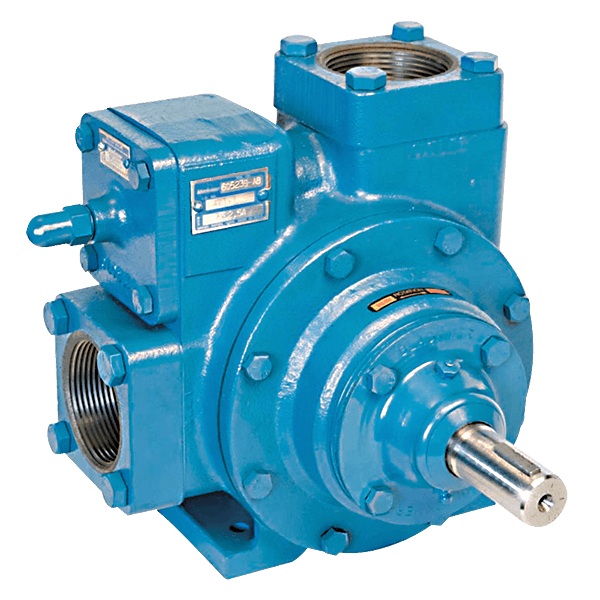

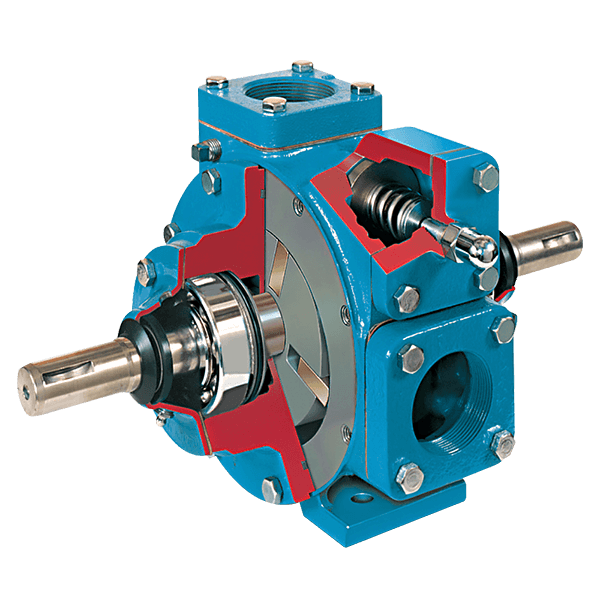

TXD Sliding Vane Pumps

Part of the Iron Line, Blackmer® TX/TXD/TXDI Series Sliding Vane Pumps are durable pumps utilized for fast and quiet operation. The sliding vane design provides sustained performance and trouble-free operation. These pumps are equipped with FKM O-rings and Blackmer mechanical seals that are compatible with all biodiesel and ethanol blends. TX/TXD/TXDI options include corrosion resistant relief valve, pneumatic relief valves and Buna or PTFE elastomers and seals.

Performance and Specifications

AVAILABLE MODELS

- TX1.5

- TXD(I)2

- TXD(I)2.5

- TXD(I)3

- TX(I)4

NOMINAL FLOW RATE

- TX1.5: 56 gpm (212 L/min)

- TXD(I)2: 87 gpm (329 L/min)

- TXD(I)2.5: 157 gpm (594 L/min)

- TXD(I)3: 270 gpm (1,022 L/min)

- TX(I)4: 505 gpm (1,911 L/min)

CATALOG OPTIONS

- Connections: NPT, Weld, Victaulic

- Elastomers: BUNA, FKM, PTFE

- Valve: Corrosion resistant

- Bypass: 1-stage or pneumatic 2-stage

- Inlet Strainer, Hydraulic Motor Adapter

DIFFERENTIAL PRESSURE

- 125 psi (8.6 bar)

MAXIMUM WORKING PRESSURE (MAWP)

- 175 psi (15.5 bar)

VISCOSITY

- 1.0 – 4250 cP

VANE MATERIALS

- Duravane

- Bronze

PRIMARY MATERIALS OF CONSTRUCTION

- TX & TXD: Cast Iron

- TXI & TXDI: Ductile Iron

CONNECTION ORIENTATION

- TX & TXD: Side Inlet | Top Outlet

- TXI & TXDI: Side Inlet | Side Outlet

TEMPERATURE

- -25°F to 240°F (-32°C to 115°C)

MIN/MAX SPEED (rpm)

- TX1.5: 200 – 800

- TXD(I)2 & TXD(I)2.5: 70 – 780

- TXD(I)3: 70 – 640

- TX(I)4: 70 – 520

AVAILABLE CERTIFICATES

- Hydrostatic Test

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimensional (pump only or unit)

Reviews

There are no reviews yet.