Description

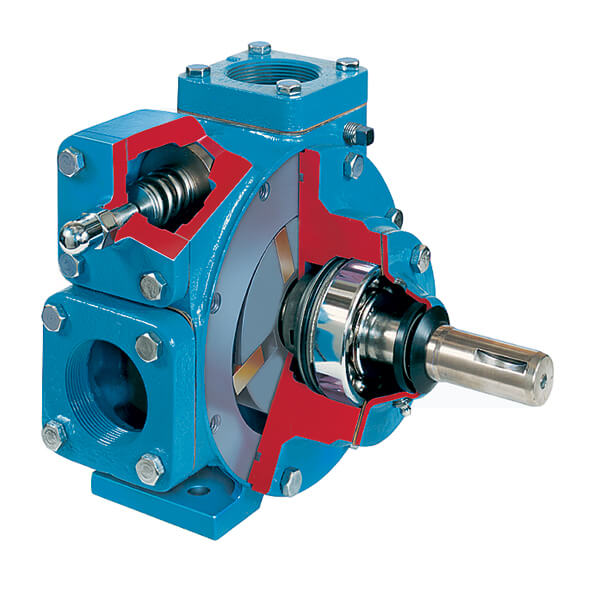

X 2-4 Sliding Vane Pumps

X model positive displacement rotary pumps, part of the Iron Line of sliding vane pumps, utilize a unique sliding vane design to offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost. Also, the high suction lift capability of these pumps makes them especially suitable for pumping from underground tanks, bulk plant service and aircraft refueling.

Blackmer® X model pumps are available in 2-, 2.5-, 3- and 4-in flanged port sizes with capacities from 10 to 520 U.S. gpm (38-1,855 L/min). Cast-iron construction is standard on all models except the X4 model which is ductile iron construction. All models have external ball bearings isolated from the pumpage by mechanical seals. X model pumps feature a 90° porting orientation, while XH model pumps have a 180° porting orientation.

Performance and Specifications

Available Models

- X2

- XH2

- X2.5

- XH2.5

- X3

- XH3

- X4

- XH4

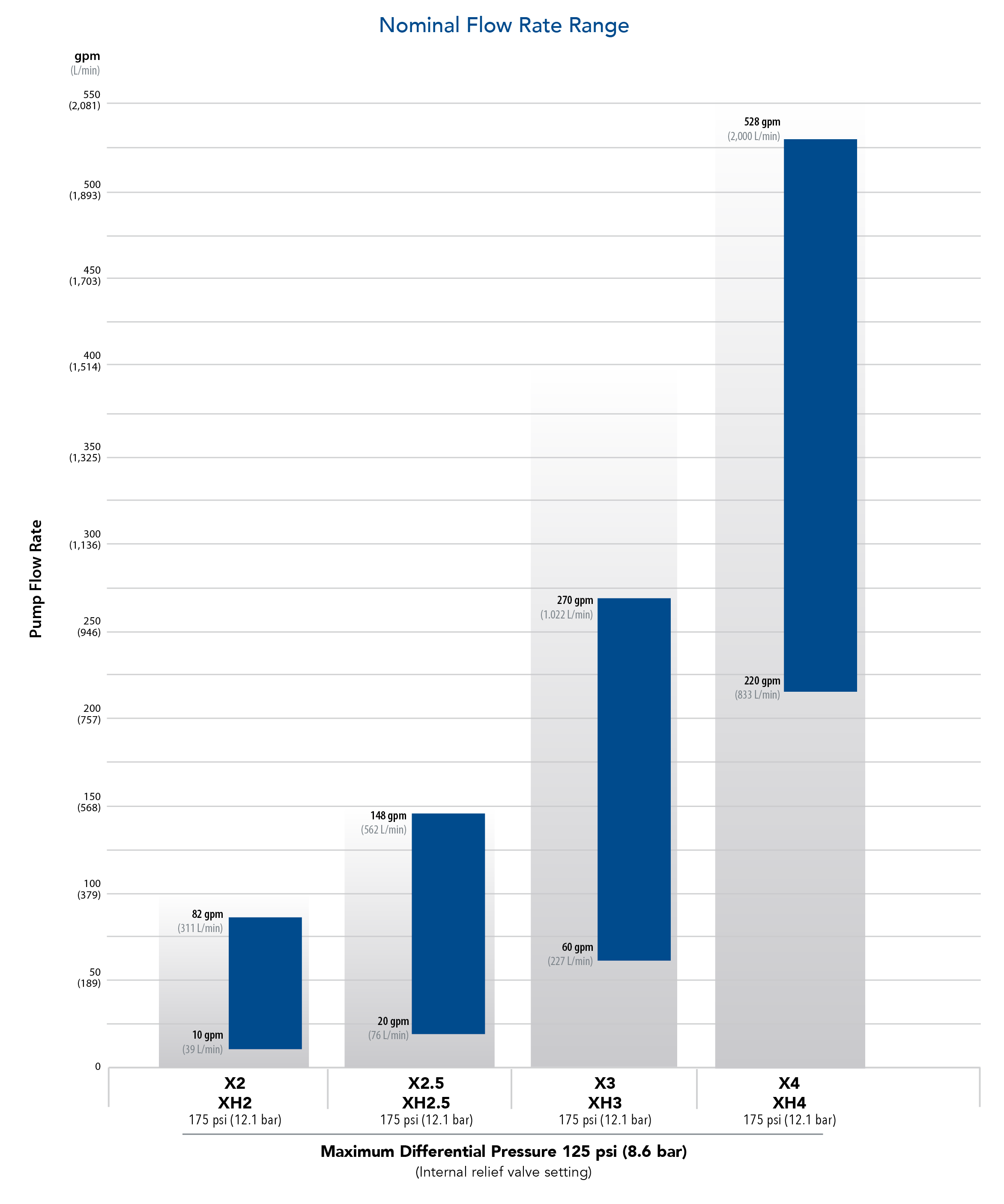

Nominal Flow Rate

- X(H)2: 10 – 82 gpm (38 – 311 L/min)

- X(H)2.5: 20 – 148 gpm (76 – 562 L/min)

- X(H)3: 60 – 270 gpm (227 – 1,022 L/min)

- X(H)4: 220 – 528 gpm (833 – 2,000 L/min)

Min/Max Speed (rpm)

- X(H)2: 70 – 780

- X(H)2.5: 70 – 780

- X(H)3: 70 – 640

- X(H)4: 70 – 520

Differential Pressure

- 125 psi (8.6 bar)

Maximum Working Pressure (MAWP)

- 175 psi (12.1 bar)

Viscosity

- 0.2 – 4,250 cP

Temperature

- -25°F to 300°F (-32°C to 148°C)

Primary Materials of Construction

- X: Cast Iron

- XH: Ductile Iron

Connection Orientation

- X: Side Inlet | Top Outlet

- XH: Side Inlet | Side Outlet

Vane Materials

- Duravane

- EC Laminate

- Bronze

- Iron

Catalog Options

- Connections: NPT, Weld, ANSI Flange

- Elastomers: BUNA, FKM, PTFE

- Seal: Blackmer single mechanical

Available Certificates

- Hydrostatic Test

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimension (pump only or unit)

Reviews

There are no reviews yet.